.png)

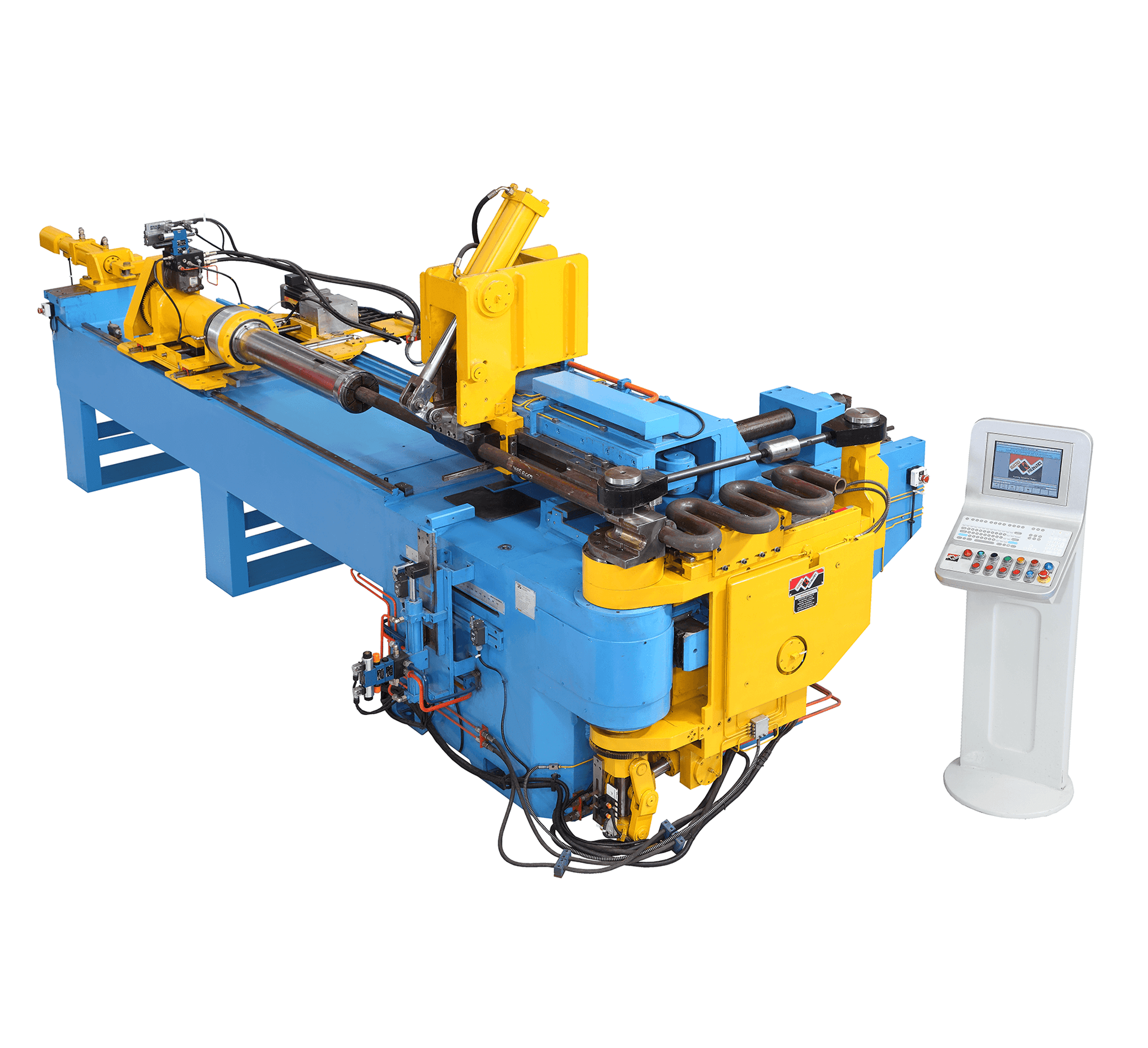

- NC Single Axis Tube Benders

- Model 30NCX for bending tubes up to OD 32 x t 2 mm

Features

- Hydraulic semi-automatic machines to produce multiple bends in a single plane

- For bending tubes of OD 3 up to 219 mm

- Open loop, programmable bend angle (DOB)

- Hydraulic direct-acting clamp and pressure die

- Independent pressure die assist (friction boost)

- Optional-extra mandrel length, extended clamp arm, counter-clockwise bending

.png)

- NC Single Axis Tube Benders

- Model 65NCX for bending tubes up to OD 65 x t 4 mm

Features

- Hydraulic semi-automatic machines to produce multiple bends in a single plane

- For bending tubes of OD 3 up to 219 mm

- Open loop, programmable bend angle (DOB)

- Hydraulic direct-acting clamp and pressure die

- Independent pressure die assist (friction boost)

- Optional-extra mandrel length, extended clamp arm, counter-clockwise bending

.png)

- NC Single Axis Tube Benders

- Model 80NCX for bending tubes up to OD 80 x t 1 mm

Features

- Hydraulic semi-automatic machines to produce multiple bends in a single plane

- For bending tubes of OD 3 up to 219 mm

- Open loop, programmable bend angle (DOB)

- Hydraulic direct-acting clamp and pressure die

- Independent pressure die assist (friction boost)

- Optional-extra mandrel length, extended clamp arm, counter-clockwise bending

.png)

- NC Single Axis Tube Benders

- Model 100NCX for bending tubes up to OD 114 x t 6 mm

Features

- Hydraulic semi-automatic machines to produce multiple bends in a single plane

- For bending tubes of OD 3 up to 219 mm

- Open loop, programmable bend angle (DOB)

- Hydraulic direct-acting clamp and pressure die

- Independent pressure die assist (friction boost)

- Optional-extra mandrel length, extended clamp arm, counter-clockwise bending

.png)

- CNC Two-Axes Tube Benders

- Model 30CNC2X for bending tubes up to OD 32 x t 2 mm

Features

- Hydraulic-electric machines to produce multiple bends in different planes

- For bending tubes of OD 3 to 219 mm

- All axes fully programmable. No manual settings.

- Push, turn powered by AC servo motors with programmable position and speed control

- Hydraulic direct-acting clamp and pressure die

- Independent pressure die assist (friction boost)

- Adaptive spring back compensation

- Split bend facility for large bend radii

.png)

- CNC Two-Axes Tube Benders

- Model 65CNC2X for bending tubes up to OD 65 x t 4 mm

Features

- Hydraulic-electric machines to produce multiple bends in different planes

- For bending tubes of OD 3 to 219 mm

- All axes fully programmable. No manual settings.

- Push, turn powered by AC servo motors with programmable position and speed control

- Hydraulic direct-acting clamp and pressure die

- Independent pressure die assist (friction boost)

- Adaptive spring back compensation

- Split bend facility for large bend radii

.png)

- CNC Two-Axes Tube Benders

- Model 80CNC2X for bending tubes up to OD 80 x t 2 mm

Features

- Hydraulic-electric machines to produce multiple bends in different planes

- For bending tubes of OD 3 to 219 mm

- All axes fully programmable. No manual settings.

- Push, turn powered by AC servo motors with programmable position and speed control

- Hydraulic direct-acting clamp and pressure die

- Independent pressure die assist (friction boost)

- Adaptive spring back compensation

- Split bend facility for large bend radii

.png)

- CNC Two-Axes Tube Benders

- Model 100CNC2X for bending of tubes up to OD 114 x t 6 mm

Features

- Hydraulic-electric machines to produce multiple bends in different planes

- For bending tubes of OD 3 to 219 mm

- All axes fully programmable. No manual settings.

- Push, turn powered by AC servo motors with programmable position and speed control

- Hydraulic direct-acting clamp and pressure die

- Independent pressure die assist (friction boost)

- Adaptive spring back compensation

- Split bend facility for large bend radii

.png)

- CNC Three-Axes Tube Benders

- Model 30CNC3X for bending tubes up to OD 32 x 2 mm

Features

- Automatic machines for high-speed production of multi-bend, multi-plane parts

- For bending tubes of OD 16 up to 419 mm

- Servo electric-hydraulic technology for auxiliary actuator with power saving up to 40%

- AC servo electric push, turn and bend axes for smaller size models

- Programmable axes motions in closed loop position and speed

- Hydraulic drop-away (or direct acting in larger models) clamp die and direct-acting pressure die

- Independent pressure die assist (friction boost)

- Split bend facility for large bend radii

- Multi-sequence bend capability for up to 5 parts with common bend radius and diameter

- Adaptive spring back compensation

- ‘SmartBend CNC’ powerful machine software with a simple, intuitive user interface

- Optional-extra mandrel length, extended clamp arm

- CNC Three-Axes Tube Benders

- Model 65CNC3X for bending tubes up to OD 65 x 3 mm

Features

- Automatic machines for high-speed production of multi-bend, multi-plane parts

- For bending tubes of OD 16 up to 419 mm

- Servo electric-hydraulic technology for auxiliary actuator with power saving up to 40%

- AC servo electric push, turn and bend axes for smaller size models

- Programmable axes motions in closed loop position and speed

- Hydraulic drop-away (or direct acting in larger models) clamp die and direct-acting pressure die

- Independent pressure die assist (friction boost)

- Split bend facility for large bend radii

- Multi-sequence bend capability for up to 5 parts with common bend radius and diameter

- Adaptive spring back compensation

- ‘SmartBend CNC’ powerful machine software with a simple, intuitive user interface

- Optional-extra mandrel length, extended clamp arm

- CNC Three-Axes Tube Benders

- Model 100CNC3X for bending tubes up to OD 114 x t 6 mm

Features

- Automatic machines for high-speed production of multi-bend, multi-plane parts

- For bending tubes of OD 16 up to 419 mm

- Servo electric-hydraulic technology for auxiliary actuator with power saving up to 40%

- AC servo electric push, turn and bend axes for smaller size models

- Programmable axes motions in closed loop position and speed

- Hydraulic drop-away (or direct acting in larger models) clamp die and direct-acting pressure die

- Independent pressure die assist (friction boost)

- Split bend facility for large bend radii

- Multi-sequence bend capability for up to 5 parts with common bend radius and diameter

- Adaptive spring back compensation

- ‘SmartBend CNC’ powerful machine software with a simple, intuitive user interface

- Optional-extra mandrel length, extended clamp arm

.png)

- CNC Three-Axes Tube Benders

- Model 400CNC3X for bending tubes up to ID 419 x t 21 mm

Features

- Automatic machines for high-speed production of multi-bend, multi-plane parts

- For bending tubes of OD 16 up to 419 mm

- Servo electric-hydraulic technology for auxiliary actuator with power saving up to 40%

- AC servo electric push, turn and bend axes for smaller size models

- Programmable axes motions in closed loop position and speed

- Hydraulic drop-away (or direct acting in larger models) clamp die and direct-acting pressure die

- Independent pressure die assist (friction boost)

- Split bend facility for large bend radii

- Multi-sequence bend capability for up to 5 parts with common bend radius and diameter

- Adaptive spring back compensation

- ‘SmartBend CNC’ powerful machine software with a simple, intuitive user interface

- Optional-extra mandrel length, extended clamp arm

.png)

- CNC Five-Axes Tube Benders (CE certified)

- Model 19CNC5X3 for bending tubes up to OD 19 x t 2 mm

Features

- Automatic, high-speed machines for bending complex, multi-radii parts efficiently

- For bending tubes of OD 10 up to 130 mm

- 3-radii bending capability in single set-up

- AC servo electric push, turn and bend axes and also lateral and vertical

- Servo electric-hydraulic technology for auxiliary actuator with power saving

- Programmable axes motions in closed loop position and speed

- Hydraulic drop-away clamp die and direct-acting pressure die

- Independent pressure die assist (friction boost)

- Split bend facility for large bend radii

- Multi-sequence bend capability for up to 5 parts with common bend radius and diameter

- Adaptive spring back compensation

- ‘SmartBend CNC’ powerful machine software with a simple, intuitive user interface

- Optional- carriage boost feature

- All-electric benders available

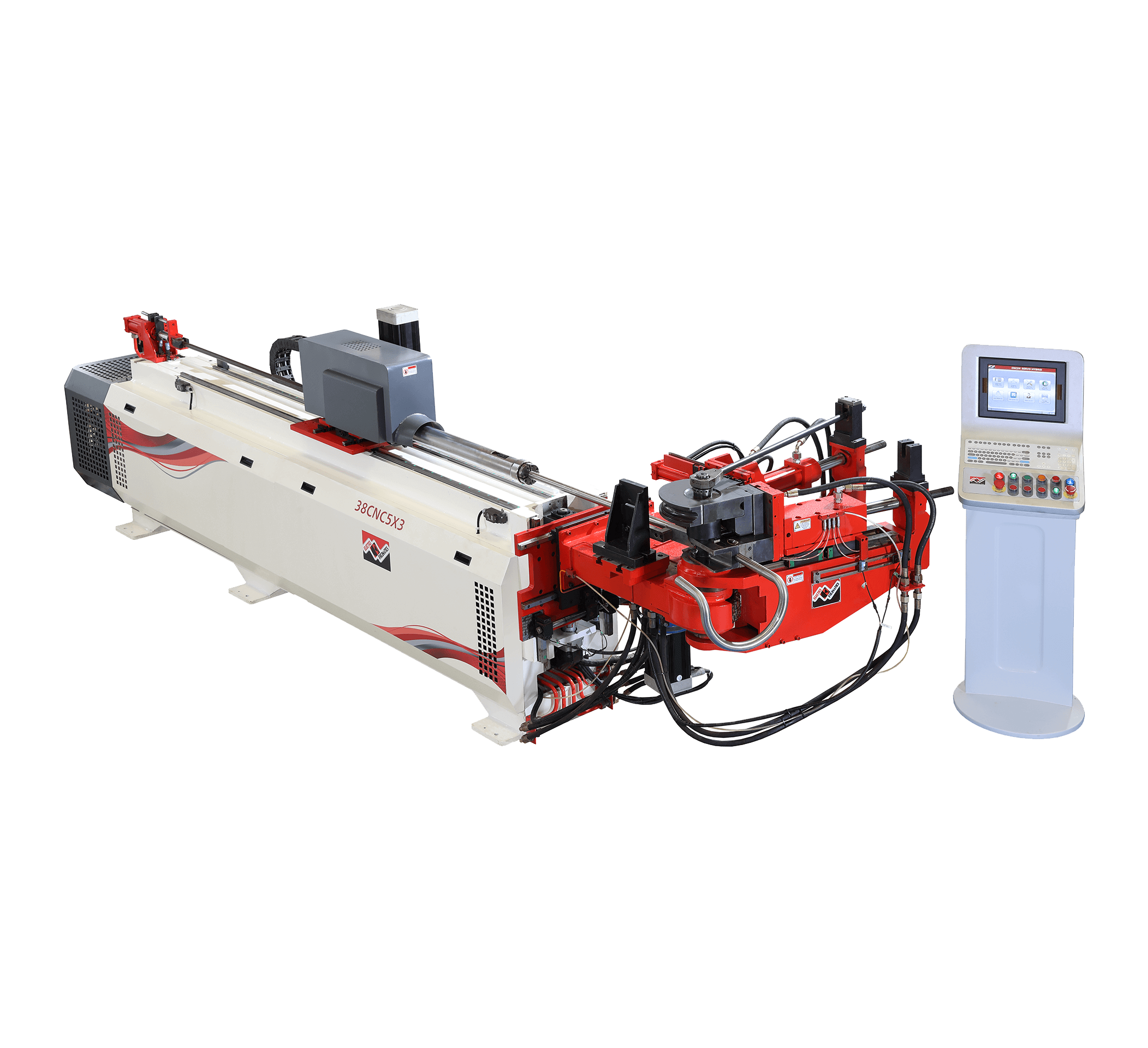

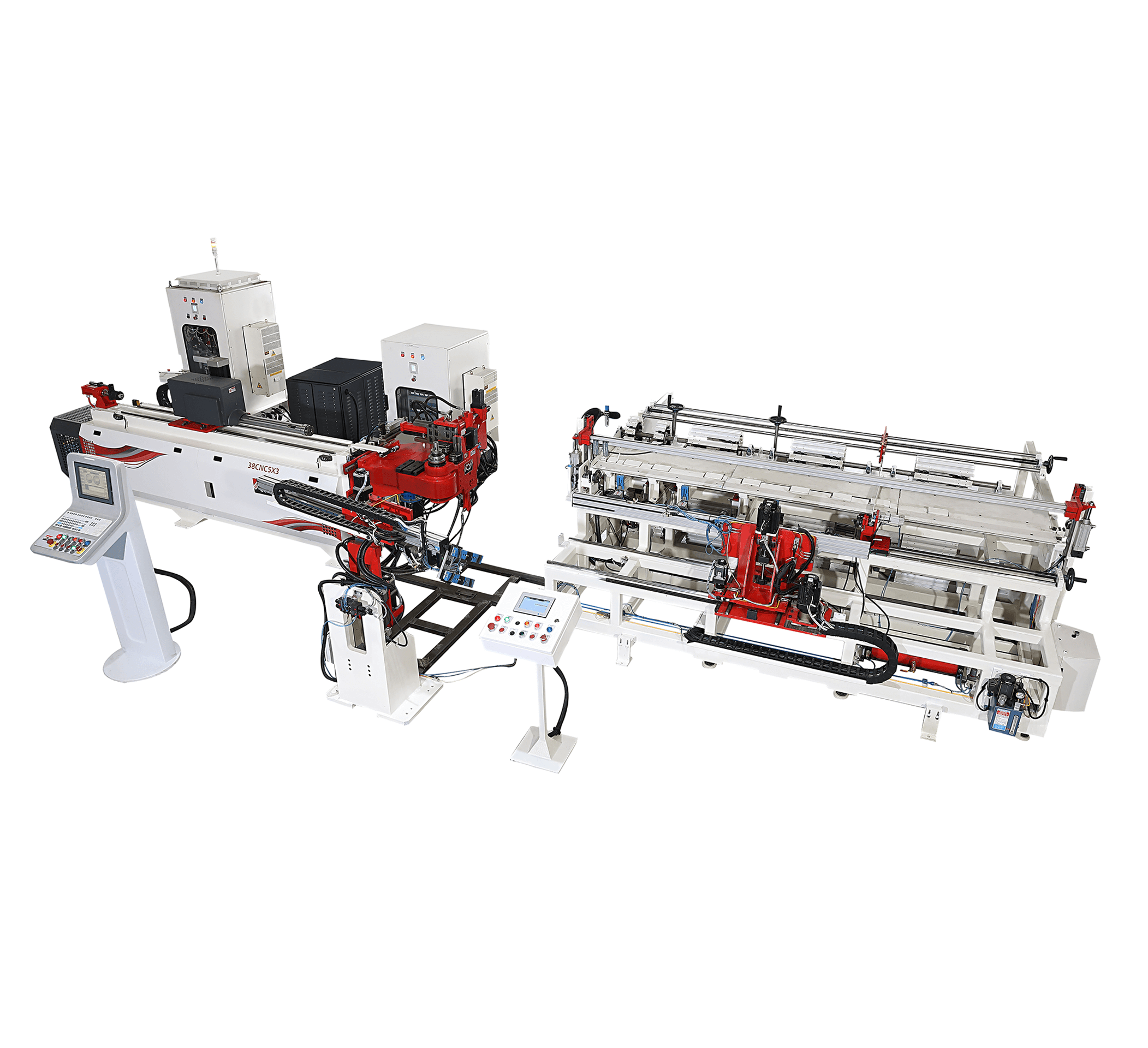

- CNC Five-Axes Tube Benders (CE certified)

- Model 38CNC5X3 for bending tubes up to OD 38 x t 2 mm

Features

- Automatic, high-speed machines for bending complex, multi-radii parts efficiently

- For bending tubes of OD 10 up to 130 mm

- 3-radii bending capability in single set-up

- AC servo electric push, turn and bend axes and also lateral and vertical

- Servo electric-hydraulic technology for auxiliary actuator with power saving

- Programmable axes motions in closed loop position and speed

- Hydraulic drop-away clamp die and direct-acting pressure die

- Independent pressure die assist (friction boost)

- Split bend facility for large bend radii

- Multi-sequence bend capability for up to 5 parts with common bend radius and diameter

- Adaptive spring back compensation

- ‘SmartBend CNC’ powerful machine software with a simple, intuitive user interface

- Optional- carriage boost feature

- All-electric benders available

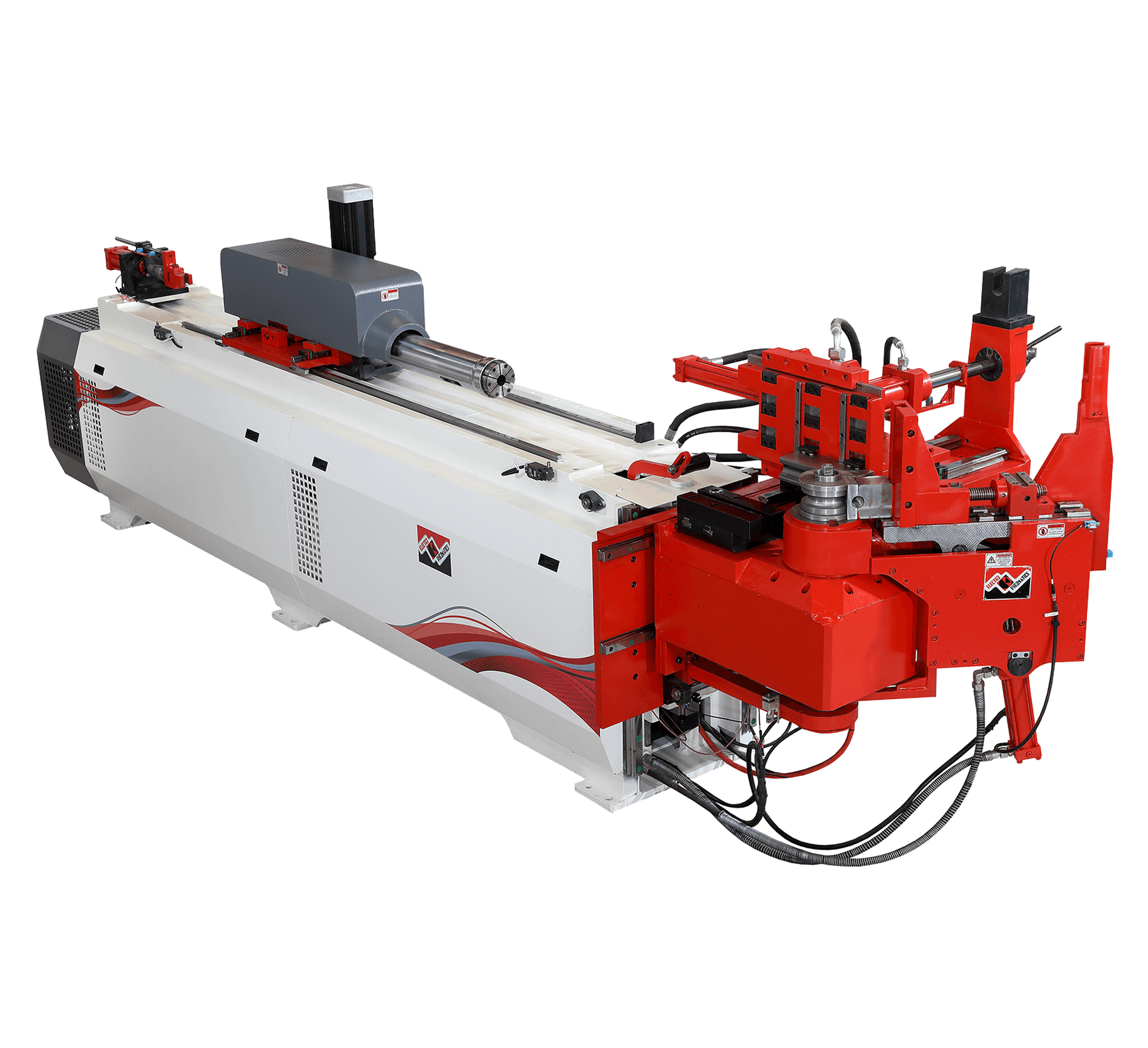

- CNC Five-Axes Tube Benders (CE certified)

- Model 65CNC5X3 for bending tubes up to OD 65 x t 3 mm

Features

- Automatic, high-speed machines for bending complex, multi-radii parts efficiently

- For bending tubes of OD 10 up to 130 mm

- 3-radii bending capability in single set-up

- AC servo electric push, turn and bend axes and also lateral and vertical

- Servo electric-hydraulic technology for auxiliary actuator with power saving

- Programmable axes motions in closed loop position and speed

- Hydraulic drop-away clamp die and direct-acting pressure die

- Independent pressure die assist (friction boost)

- Split bend facility for large bend radii

- Multi-sequence bend capability for up to 5 parts with common bend radius and diameter

- Adaptive spring back compensation

- ‘SmartBend CNC’ powerful machine software with a simple, intuitive user interface

- Optional- carriage boost feature

- All-electric benders available

_1.png)

- CNC Five-Axes Tube Benders (CE certified)

- Model 90CNC5X3 for bending tubes up to OD 90 x t 3 mm

Features

- Automatic, high-speed machines for bending complex, multi-radii parts efficiently

- For bending tubes of OD 10 up to 130 mm

- 3-radii bending capability in single set-up

- AC servo electric push, turn and bend axes and also lateral and vertical

- Servo electric-hydraulic technology for auxiliary actuator with power saving

- Programmable axes motions in closed loop position and speed

- Hydraulic drop-away clamp die and direct-acting pressure die

- Independent pressure die assist (friction boost)

- Split bend facility for large bend radii

- Multi-sequence bend capability for up to 5 parts with common bend radius and diameter

- Adaptive spring back compensation

- ‘SmartBend CNC’ powerful machine software with a simple, intuitive user interface

- Optional- carriage boost feature

- All-electric benders available

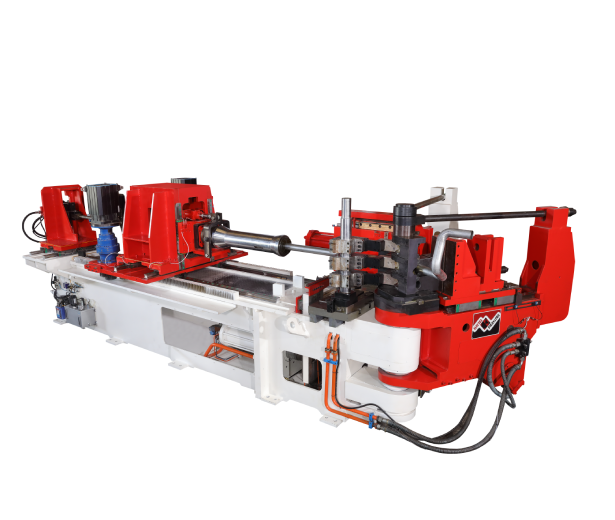

- CNC Five-Axes Tube Benders

- Model 115CNC5X2 for bending of tubes up to OD 114 x t 3 mm

Features

- Automatic, high-speed machines for bending complex, multi-radii parts efficiently

- For bending tubes of OD 10 up to 130 mm

- 3-radii bending capability in single set-up

- AC servo electric push, turn and bend axes and also lateral and vertical

- Servo electric-hydraulic technology for auxiliary actuator with power saving

- Programmable axes motions in closed loop position and speed

- Hydraulic drop-away clamp die and direct-acting pressure die

- Independent pressure die assist (friction boost)

- Split bend facility for large bend radii

- Multi-sequence bend capability for up to 5 parts with common bend radius and diameter

- Adaptive spring back compensation

- ‘SmartBend CNC’ powerful machine software with a simple, intuitive user interface

- Optional- carriage boost feature

- All-electric benders available

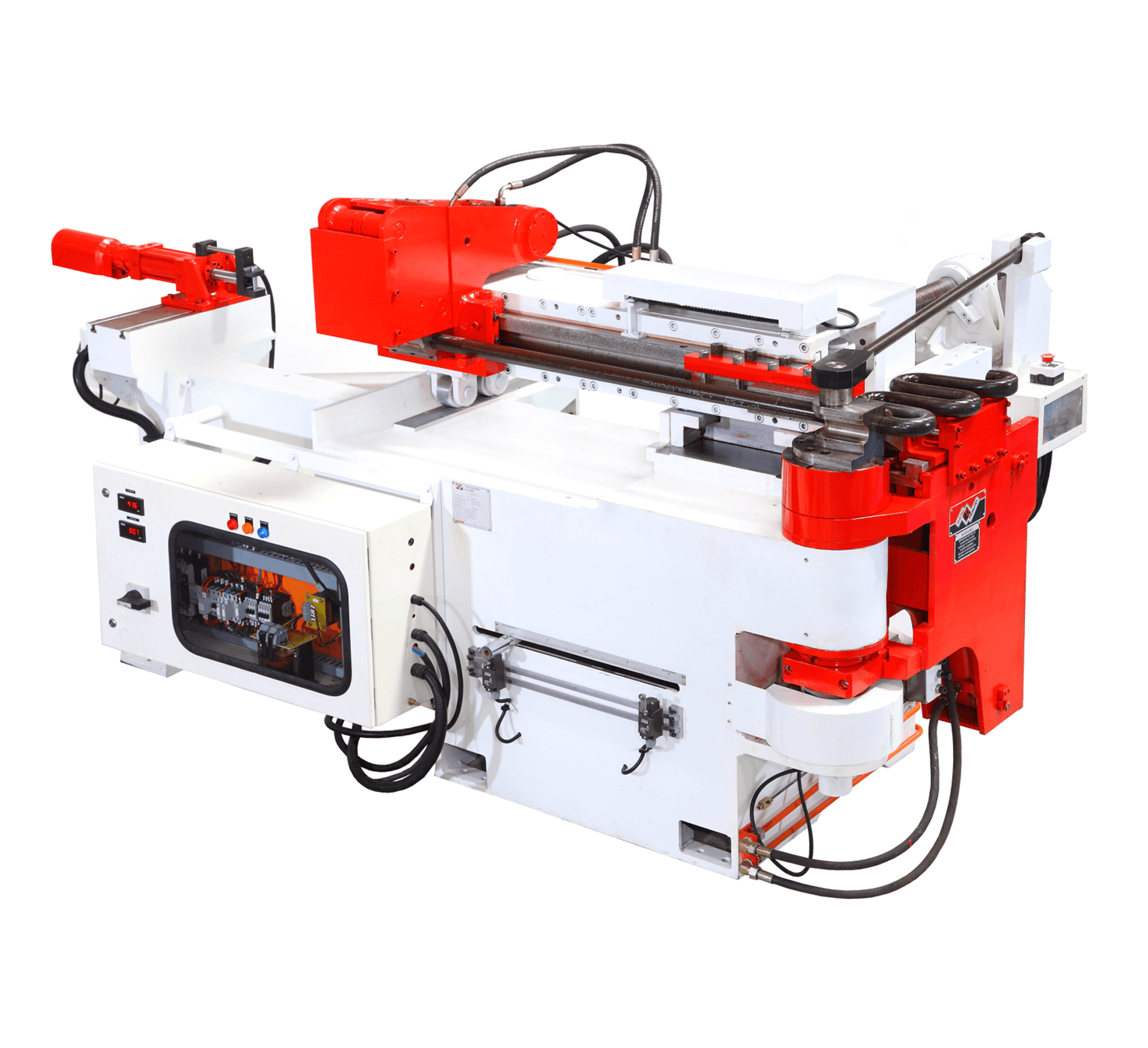

- CNC All-Electric Tube Benders

- Model 32CNC9X3-LR for bending of tubes up to OD 32 x t 2 mm

Features

- Bi-directional bending for complicated profiles

- All 9-axes driven by AC electric servo for better speed, accuracy and flexibility

- 3 stacks for bending different radii

- High productivity by optimised parallel axes motions with programmable closed loop position-speed control

- Clean and quiet operations

- Data entry as push-turn-bend (Y-B-C) values or X-Y-Z co-ordinates

- Comprehensive online diagnostics

- Electropneumatics make Smart Bend CNC system with our powerful and simple Linux based touch screen CNC software with intuitive user interface.

- Independent pressure die assist (friction boost)

- Automatic self-lubrication for LM guide

- Remote access using team viewer software

- Auto diagnosis feature for trouble shooting

- CNC All-Electric Tube Benders

- Model 38CNC9x3-LR for bending of tubes up to OD 38 x t 4 mm

Features

- Bi-directional bending for complicated profiles

- All 9-axes driven by AC electric servo for better speed, accuracy and flexibility

- 3 stacks for bending different radii

- High productivity by optimised parallel axes motions with programmable closed loop position-speed control

- Clean and quiet operations

- Data entry as push-turn-bend (Y-B-C) values or X-Y-Z co-ordinates

- Comprehensive online diagnostics

- Electropneumatics make Smart Bend CNC system with our powerful and simple Linux based touch screen CNC software with intuitive user interface.

- Independent pressure die assist (friction boost)

- Automatic self-lubrication for LM guide

- Remote access using team viewer software

- Auto diagnosis feature for trouble shooting

- CNC 1D Tube Benders

- Model 65CNC5X3-1D for bending of thin-walled SS tubes up to OD 63.5 x t 2 m

Features

- 3-radii bending and parts with less distance between bends possible with 3-stack tooling in a single set up

- Push, turn, bend, lateral and vertical axes powered by AC servo motors

- Servo pump driven auxiliary functions, i.e., clamp, pressure die assist, chuck and mandrel for energy efficiency, less heat generation and reduced noise

- Programmable closed loop position-speed control with optimised parallel axes motion

- Independent pressure die assist (friction boost)

- Carriage boost facility for bending tight bends less than 1.5D up to 1D with good control on thinning

- Automatic self-lubrication for LM guides

- Remote access using team viewer software

- Auto diagnosis feature for trouble shooting

- CNC 1D Tube Benders

- Model 100CNC5X3-1D for bending of thin-walled SS tubes up to OD 101.6 x t 2.11 mm

Features

- 3-radii bending and parts with less distance between bends possible with 3-stack tooling in a single set up

- Push, turn, bend, lateral and vertical axes powered by AC servo motors

- Servo pump driven auxiliary functions, i.e., clamp, pressure die assist, chuck and mandrel for energy efficiency, less heat generation and reduced noise

- Programmable closed loop position-speed control with optimised parallel axes motion

- Independent pressure die assist (friction boost)

- Carriage boost facility for bending tight bends less than 1.5D up to 1D with good control on thinning

- Automatic self-lubrication for LM guides

- Remote access using team viewer software

- Auto diagnosis feature for trouble shooting

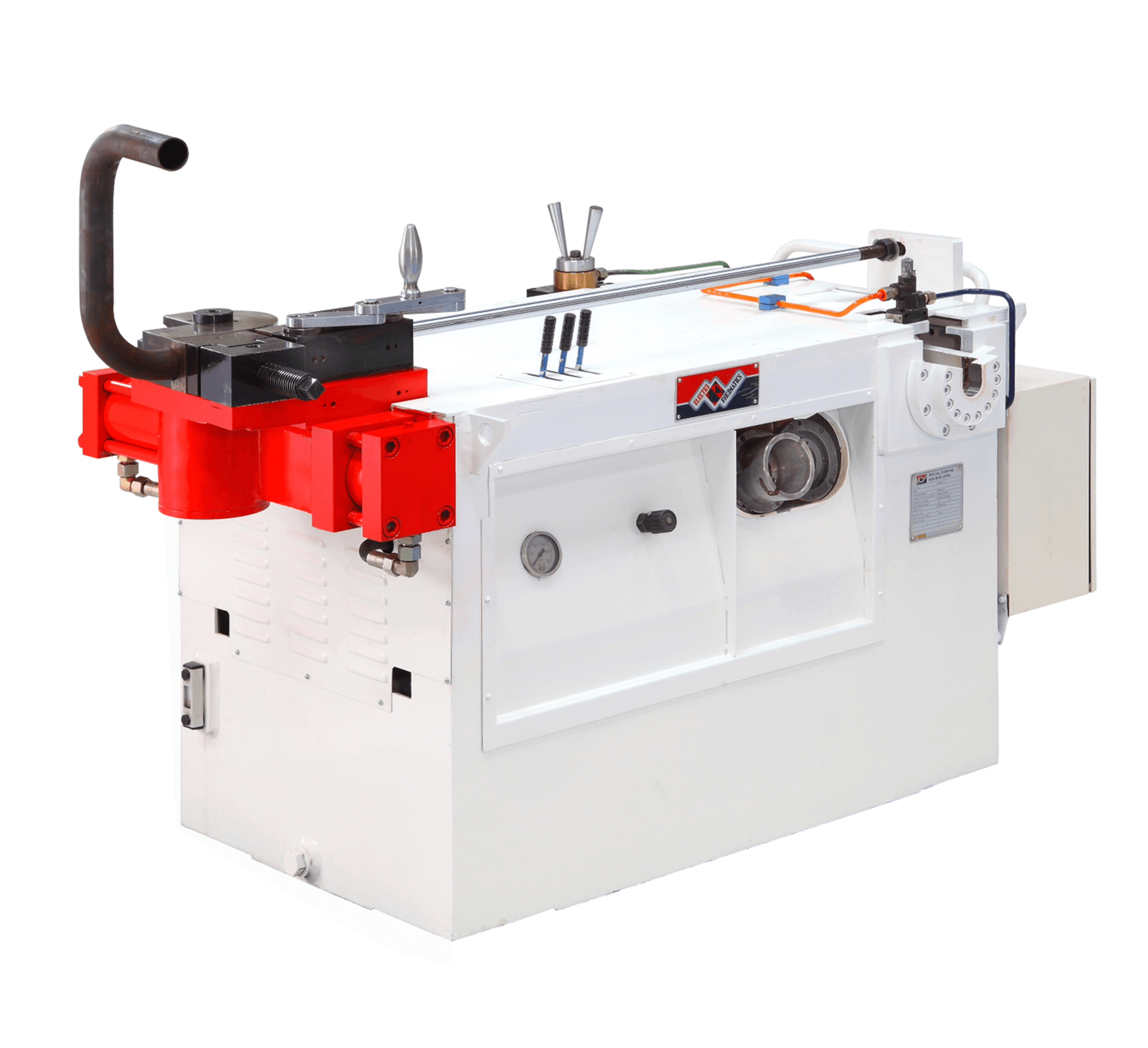

- CNC Boost Benders

- Model 65CNC2X-B for bending tubes up to OD 63.5 x t 7.1 mm

Features

- Automatic machines that meet the stringent ovality/thinning requirements of bending thick-walled, tight-radius tubes required in boiler, chemical and process industries

- For bending tubes of OD 63.5 up to 114 mm in normal and boost mode

- Minimum radius 1D on tubes with D/t < 9

- 8-10% ovality and 12-13% thinning on 1D bends

- Capability of serpentine bending with suitable tooling

- Synchronisation and programmability of bend-boost speed and position through servo controls

- Mandrel-less and tie rod-less boost bending

- Optional-extra mandrel length, split tool arrangement for CLR > 57 mm

- CNC Boost Benders

- Model 100CNC2X-B for bending tubes up to OD 114 x t 6 mm

Features

- Automatic machines that meet the stringent ovality/thinning requirements of bending thick-walled, tight-radius tubes required in boiler, chemical and process industries

- For bending tubes of OD 63.5 up to 114 mm in normal and boost mode

- Minimum radius 1D on tubes with D/t < 9

- 8-10% ovality and 12-13% thinning on 1D bends

- Capability of serpentine bending with suitable tooling

- Synchronisation and programmability of bend-boost speed and position through servo controls

- Mandrel-less and tie rod-less boost bending

- Optional-extra mandrel length, split tool arrangement for CLR > 57 mm

- Special Tube Benders

- Section benders for oval, square, rectangular and other sections

- Model 130CNC5X2 for bending of tubes up to OD 130 x t 5 mm

Features

- Machines for bending non-round tube sections like square, rectangular, oval, etc.

- Suitable for chassis long members of jeeps, trucks and commercial vehicles, and sections used in luggage frames, furniture frames, automobile accessories, etc.

- 2-3 radii bending capability with 2-3 stack tooling in single set-up

- Push, turn, bend, lateral and vertical powered by AC servo motors

- Servo-pump driven energy-efficient, low noise, low maintenance hydraulic system

- Programmable axes motion in closed loop position and speed

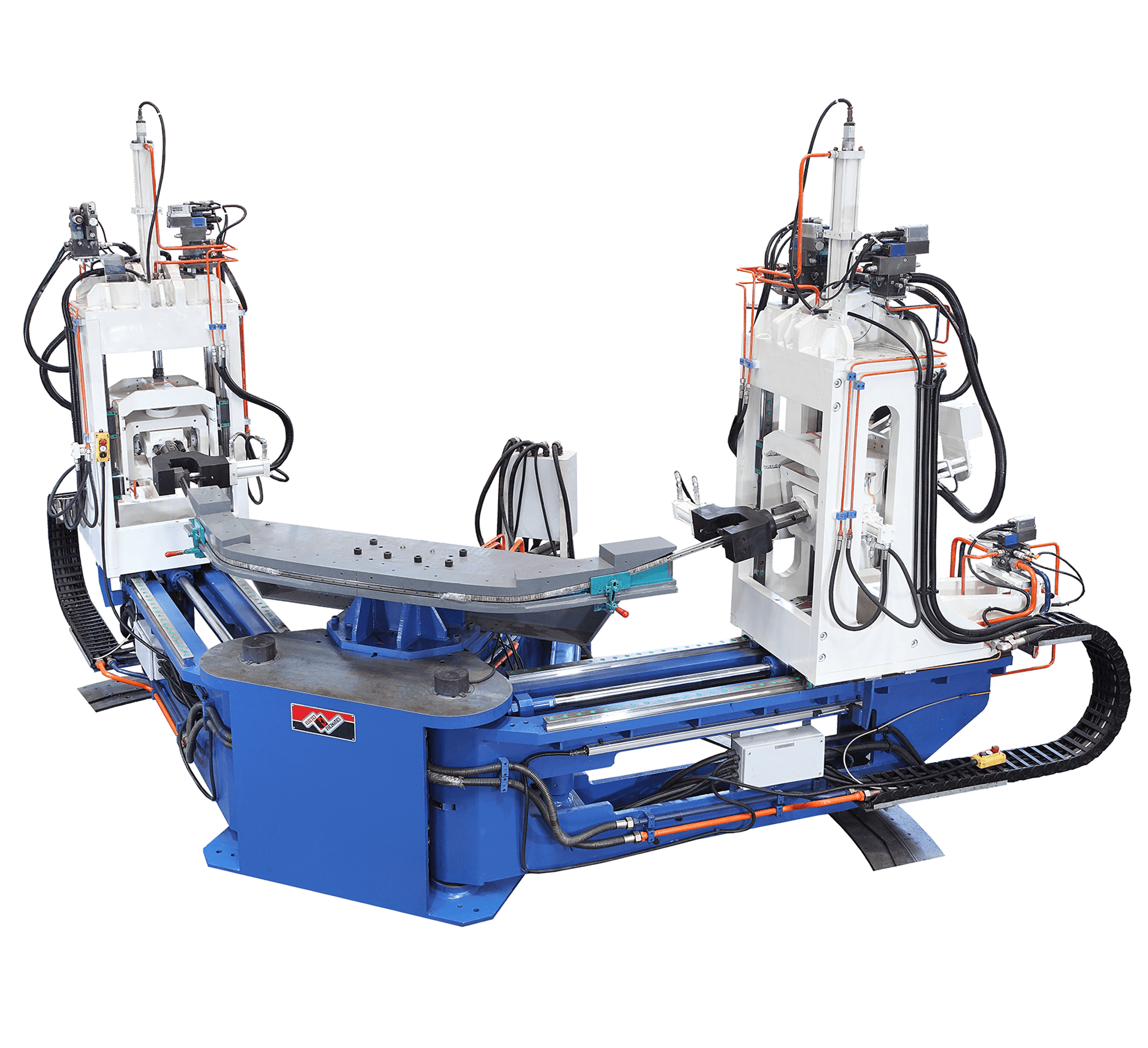

- Special Tube Benders

- Stretch benders

Features

- Designed and made to specific customer requirements

- Can be equipped with different levels of automation and accessories

CNC 8-axes hydraulic stretch bender

- Produces complex, multi-plane bend shapes in rolled sections used in automobile windows, door frames, etc.

- Eight servo hydraulic axes with synchronised speed with respect to each other

- Fully programmable

- Variations available

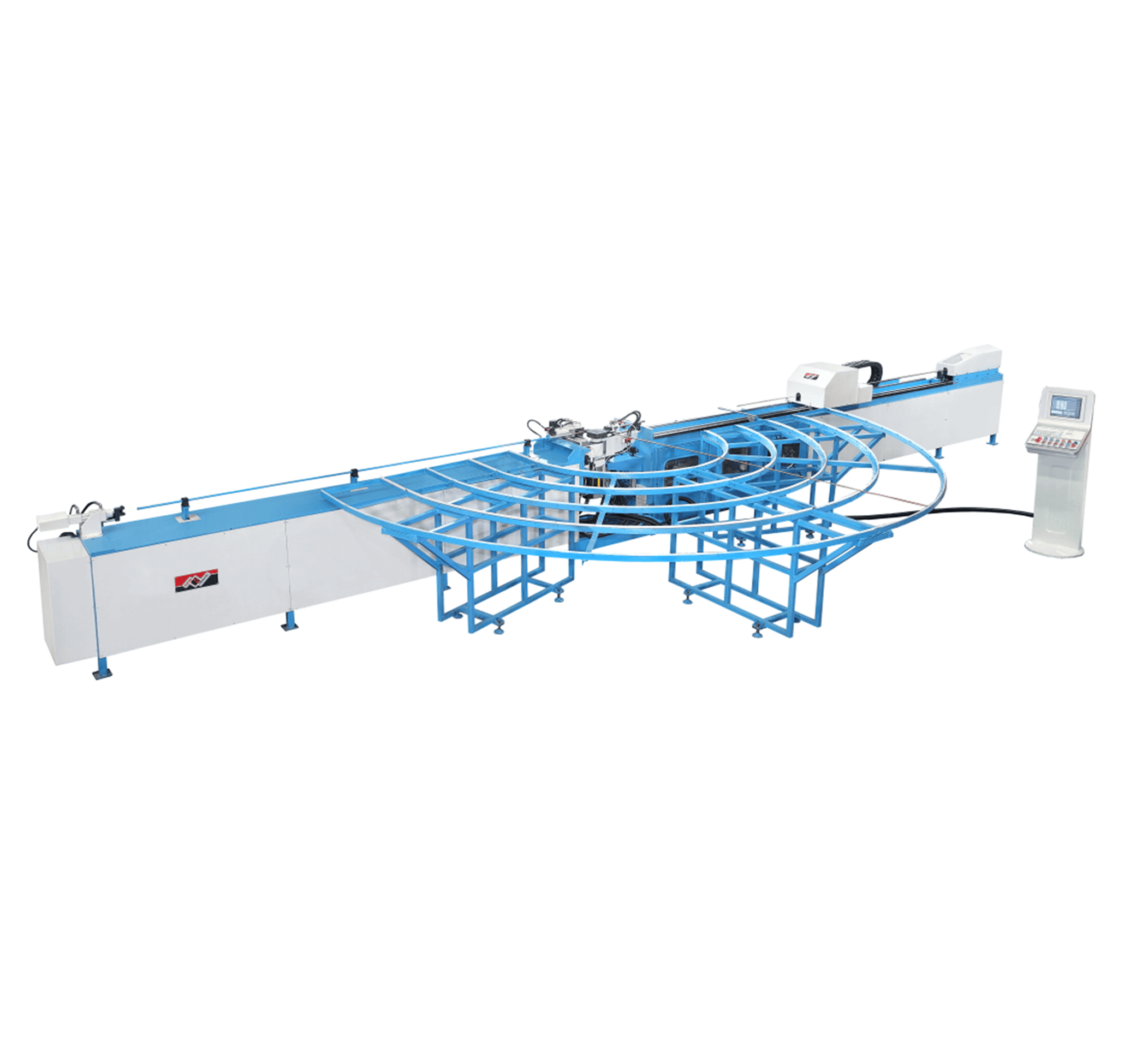

- Special Tube Benders

- U-bender for long copper tubes

Features

- Designed and made to specific customer requirements

- Can be equipped with different levels of automation and accessories

U-bender

- Special purpose 2-axes bender for U-bending of smaller diameter, long copper tubes of HVAC industries

- With automatic feeding from coil, straightening, cutting as per programmed length

- Suitable for tight bends (up to 1D)

- Special Tube Benders

- Portabend tube working stations for piping requirements

Features

- Designed and made to specific customer requirements

- Can be equipped with different levels of automation and accessories

Portabend

- A universal mobile multi-purpose tube working station

- Comprises of a swaing, ID/OD deburring, bending and ferrule pre-setting unit

- Most suitable for hydraulic piping work in factories, and also for on-board and off-shore tasks

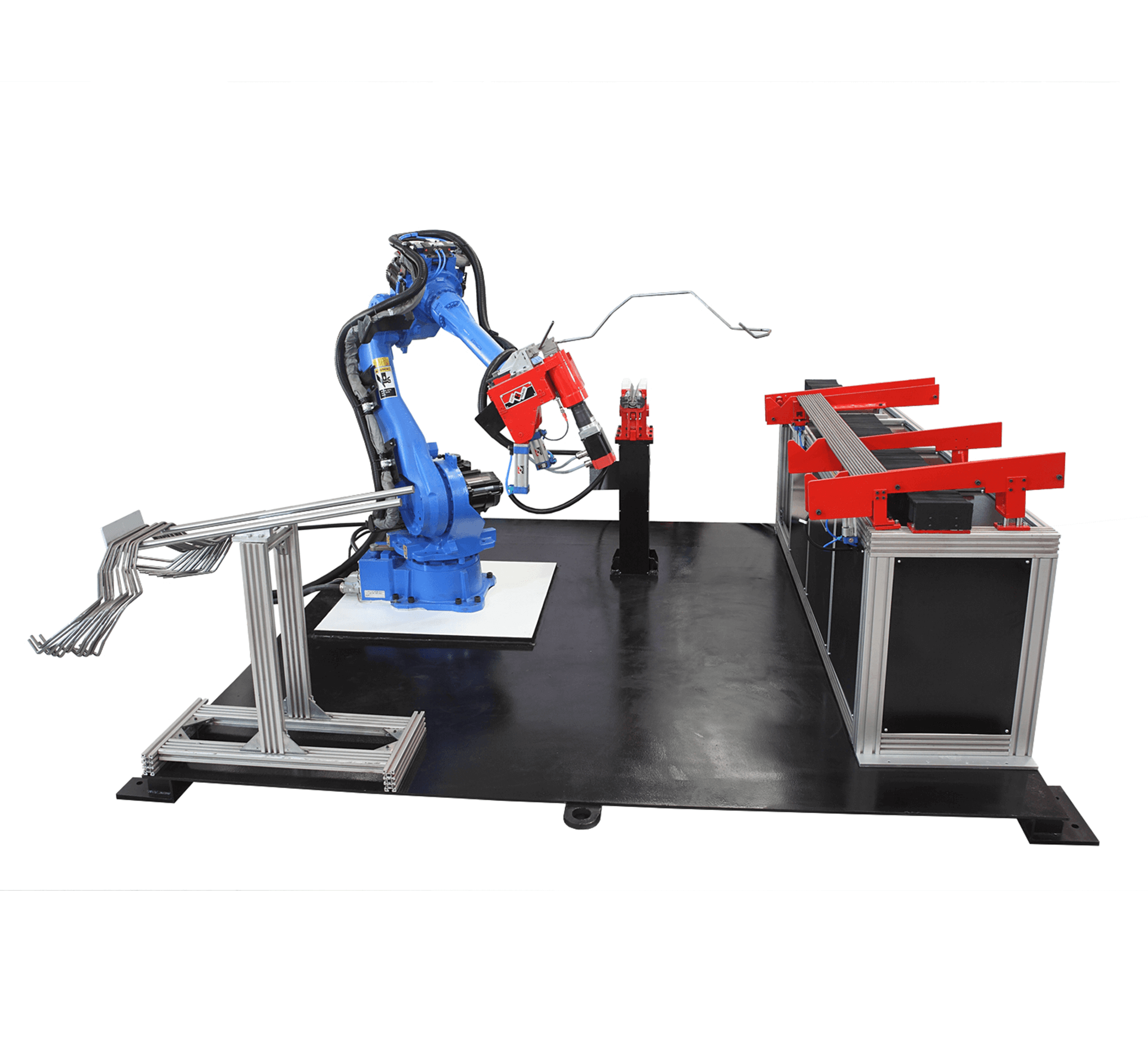

- Special Tube Benders

- Robotic benders

Features

- Designed and made to specific customer requirements

- Can be equipped with different levels of automation and accessories

Robotic benders

- Specially designed bending head mounted on a 6-axes robot, integrated with a tube magazine

- For interference-free, mandrel-less, consistent and high-speed bending of small diameter tubes in large volumes

- Special Tube Benders

- Automated bending cells for customised, unmanned high-speed, repeatable bending

Features

- Designed and made to specific customer requirements

- Can be equipped with different levels of automation and accessories

Robotic Bending Cells

- Comprises of multiple benders, an tube unloader and a 6-axes robot

- For loading and unloading tubes in benders with minimum downtime

- Cuts down manpower requirement and ensures repeatable productivity

- Special Tube Benders

- Automated bending cells for customised, unmanned high-speed, repeatable bending

Features

- Designed and made to specific customer requirements

- Can be equipped with different levels of automation and accessories

3-axes and 5-axes CNC tube bending cells with automated loading and unloading

- Designed, manufactured and delivered in multiple nos. for bending a variety of tube sizes for the healthcare industry

- High productivity and consistent repeatability

- Equipped with auto loading and unloading system, and tube hole detection system

- Optimum cycle time through simultaneous operation sequencing

- Just the push of a button is needed to produce consistent, repeatable parts without human interaction.

- 24 tools and inspection gauges supplied along with each machine for producing different parts

.png)